Vibrating wire sensor. Vibrating wire sensor.

My grandfather, Armin Wirth, made his fortune inventing weighing scales, machines to weigh everything from ladles full of molten steel to airplanes to powdered sugar. But his enduring contribution to the technology of weighing was the invention of the vibrating wire sensor.

The idea is quite simple: A wire is stretched between two points and caused to vibrate by an alternating current running through it (magnets around the wire have been removed in this photo so you can see the wire). As anyone who has tuned a guitar knows, the resonant frequency of a stretched wire depends on how tightly it is stretched. In other words, the frequency is a measurement of the force stretching the wire, and therein lies a sensor.

The Wirth-Gallo company first started building sensors based on this principle decades ago, but pictured here is a modern incarnation, a compact, relatively inexpensive aluminum unit. You can see the wire stretched across the center near the top of the unit. It's held on either side by a pair of sapphire cylinders squeezed together by conical steel pins pressed into the opposite sides of the two blocks on top.

In use, the force to be measured is applied to a rod inserted through the hole in the thick bottom section and fastened with set screws to the block in the center of the machined aluminum unit. As you can see from the geometry of the device, if you push up on the center block it will deflect upwards, causing the two sets of horizontal supports to angle outwards (going from rectangular to parallelogram shape), which in turn will cause the two blocks holding the wire to be pulled farther apart.

Of course the actual movement is microscopic: The mechanism is designed to transfer force to the wire, not actually move any significant amount. (In fact the whole complex geometry is designed to minimize the negative effects, like metal creep and fatigue, that come about from whatever movement there is.)

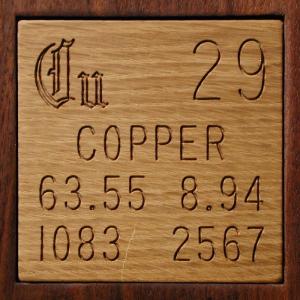

If you look at the rotation video you can see how much effort goes into isolating the wire holding block from error forces. For example, elaborately shaped bits of copper connect the ends of the stretched wire to the circuit board.

You may be forgiven for asking, why not just use a Piezo electric crystal force sensor? Piezo sensors are ubiquitous, and they work fine in many applications, but they have limitations, one of which is that it's difficult to keep them accurate under severe operating conditions.

For example, imagine wanting to be able to weigh the garbage collected from each individual house on a collection route, by putting sensors on all four wheels of the garbage truck. (This is not only being done in Europe, in a number of countries it is or soon will be a legal requirement that all garbage collection service by priced by the pound. It tends to make people think a bit more about what they throw away.)

Sensors on the wheels of a garbage truck have what can only be described as a hard life. One minute they are being run over pot holes at high speed, slamming a truck weighing many tons down hard on the sensor. The next minute they are being asked to accurately weigh a few pounds of garbage, by measuring the increases in weight of the multi-ton truck when a new bin is tipped into it.

That's the kind of job for which the vibrating wire sensor has a great advantage over the more delicate Piezo sensors, which tend to drift out of calibration when subject to such rude treatment.

My uncle Johannes Wirth, who took over the business from my grandfather, gave me this sensor when I visited him recently in Zurich (taking my whole family including three smallish children on a two week vacation to London and Switzerland, but that's a whole other story).

Source: Johannes Wirth

Contributor: Johannes Wirth

Acquired: 4 September, 2007

Text Updated: 5 September, 2007

Price: Donated

Size: 2"

Purity: >60%

|

|

|

|